Automotive industry

In the field of traditional fuel-powered vehicles, die casting is widely used in engines, transmissions, and chassis systems, such as cylinder blocks, cylinder heads, transmission housings, and suspension components, which require high strength, heat resistance, and wear resistance. In body structural components, die casting is also used to manufacture door frames, A/B/C pillars, and other components to meet the requirements of lightweight and collision safety.

Electronic communication

Die casting technology can efficiently manufacture lightweight alloy components such as aluminum alloy and magnesium alloy, including mobile phone frames, base station heat sinks, and antenna housings. These components not only have excellent mechanical properties and electromagnetic shielding effects, but also significantly improve the heat dissipation efficiency of the equipment, ensuring the stable operation of communication equipment.

Home appliance industry

Home appliances have high requirements for the strength, heat dissipation performance, and lightweight design of their components. Die casting can efficiently produce metal parts with good mechanical properties and corrosion resistance, and can also meet the aesthetic and functional integration requirements of home appliances. It can also achieve complex structures in a single molding process, reducing assembly procedures, improving production efficiency, and lowering costs.

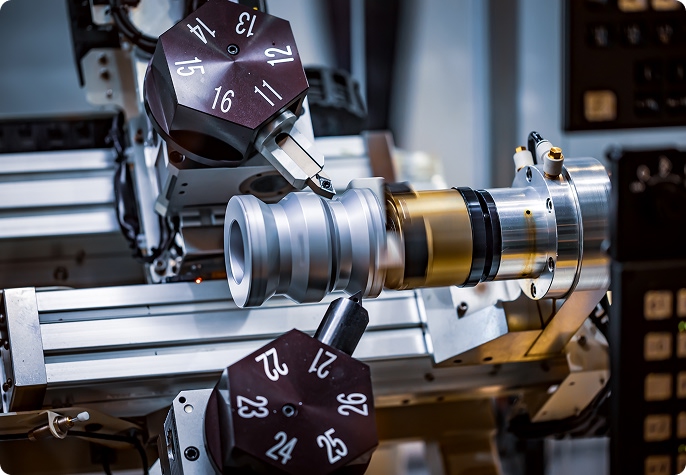

Mechanical engineering

Mechanical manufacturing places extremely high demands on the wear resistance, impact resistance, and dimensional stability of components. However, gears, housings, brackets, and connecting parts manufactured using die casting not only have excellent mechanical properties and corrosion resistance, but also meet the requirements of mechanical equipment for lightweight and integrated designs.