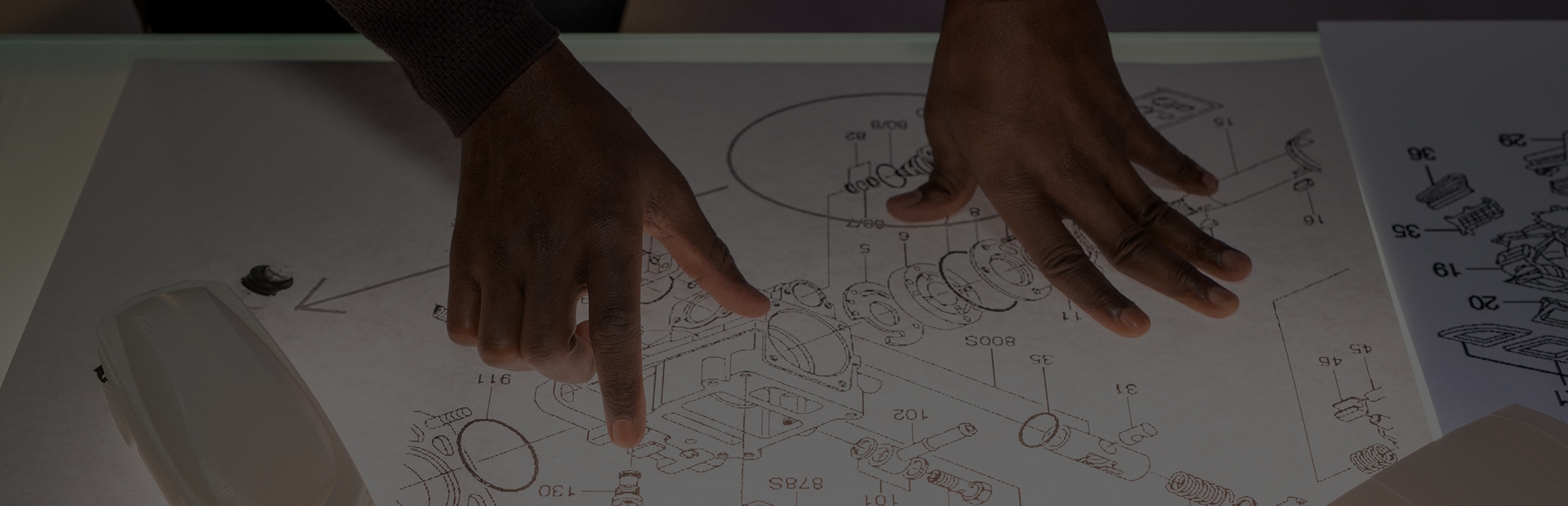

Advanced Metal Manufacturing for Global OEM Projects

With extensive experience in integrated metal manufacturing, Meituo has built a production system that connects design, engineering, and manufacturing into one continuous process. Our facilities combine advanced die casting, machining, and finishing technologies with data-driven control, ensuring stable quality and consistent performance from product development to large-scale production.

our capabilities

Integrated Manufacturing Capabilities Overview

Meituo's six major manufacturing capabilities enable comprehensive OEM metal production support. Each process is managed with precision engineering and quality systems to ensure seamless integration and scalable output.

Mold Design & Tooling

Our in-house design team uses advanced software such as UG and JSCAST for mold simulation and optimization, ensuring accuracy in shrinkage, draft angles, and cooling design for high-quality production.

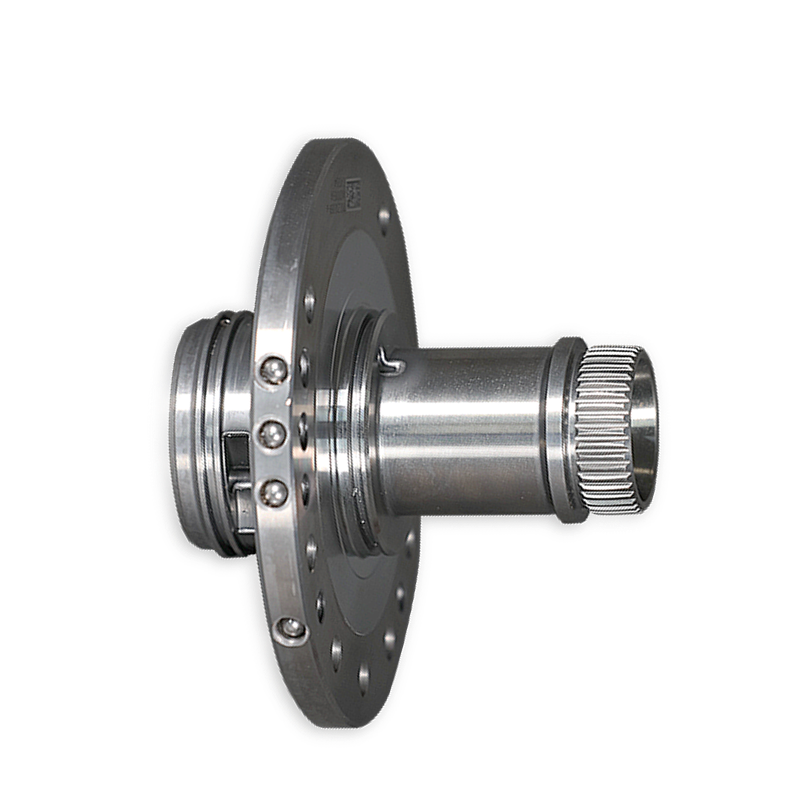

Die Casting

Equipped with 160T–1650T die casting machines, Meituo specializes in aluminum and zinc alloy die casting for complex parts with tight tolerances and superior strength, serving industries from appliances to automotive.

CNC Machining

Our machining centers feature over 100 CNC units, providing high-precision turning, milling, and drilling for both large structural parts and detailed components with strict dimensional requirements.

Stamping & Forming

We operate 39 precision presses ranging from 16T to 200T, producing stamped components with excellent repeatability, shape accuracy, and efficiency for high-volume manufacturing.

Surface Finishing

From polishing and powder coating to anodizing and plating, our finishing services enhance corrosion resistance and appearance to meet specific customer and industry requirements.

Assembly & Integration

Our modular assembly lines combine metal, plastic, and electronic components into complete subassemblies, ensuring efficient integration, reduced lead times, and consistent quality output.

Quality Assurance

Certified Manufacturing Excellence

Our commitment to quality is demonstrated through ISO9001, ISO14001, ISO45001, and IATF16949 certifications. Every production stage follows strict quality control protocols to ensure consistent performance and reliability.

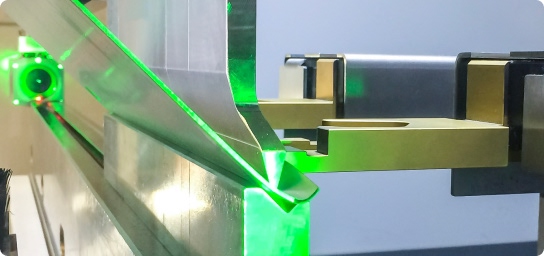

Advanced Manufacturing Equipment

Meituo's production facilities include advanced die casting machines, automated CNC machining centers, and specialized testing instruments. Our equipment enables high repeatability, consistent precision, and scalability across diverse metal manufacturing processes.

Engineering & Technical Team

Our team of 300+ professionals includes more than 50 senior engineers and technical experts with postgraduate or university degrees. They work closely with overseas consultants from Japan and Taiwan, as well as domestic universities, to drive continuous innovation and process optimization.

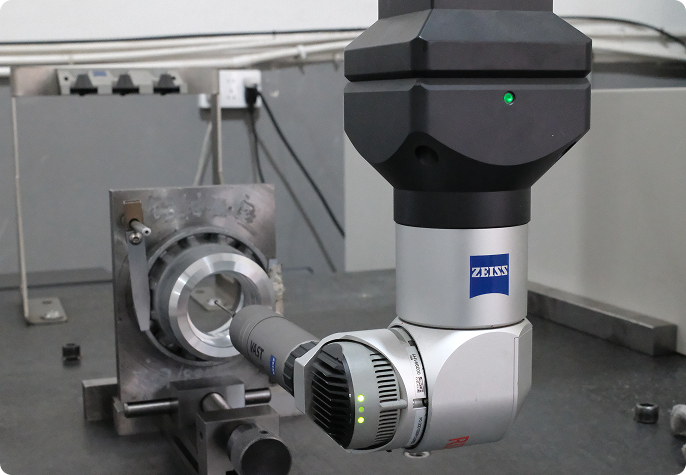

Quality Control & Inspection

Every production step is managed under IATF16949 and ISO9001 systems. Meituo employs advanced testing equipment including hardness testers, spectrometers, salt spray chambers, tensile testing machines, Zeiss 3D coordinate systems, and X-ray detectors to ensure part quality, consistency, and compliance.

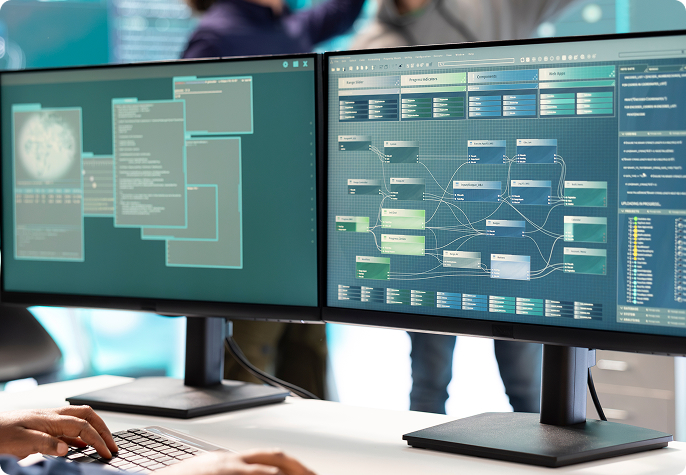

Digital Manufacturing Systems

Through the integration of MES, PDM, and QMS digital platforms, Meituo achieves real-time process monitoring, production traceability, and data-driven quality management. These systems enhance transparency and efficiency across every manufacturing stage.

Manufacturing Process Flow

From Design to Delivery

Quality Systems You Can Trust

Certified Manufacturing Assurance

Every part we produce is backed by internationally recognized certifications and continuous quality monitoring.

Meituo operates under globally recognized quality systems including IATF16949, ISO9001, ISO14001, ISO45001, ISO14064, and ISO50001. These certifications ensure compliance with international manufacturing and environmental standards across all processes.

Meituo operates under globally recognized quality systems including IATF16949, ISO9001, ISO14001, ISO45001, ISO14064, and ISO50001. These certifications ensure compliance with international manufacturing and environmental standards across all processes.

Sustainability & Responsibility

Sustainable Metal Manufacturing

Meituo promotes green production practices through energy-efficient operations, ISO14064 greenhouse gas verification, and ISO50001 energy management certification. Our digital management and process optimization systems reduce waste and emissions, supporting sustainable growth and environmental responsibility in the global metal manufacturing industry.