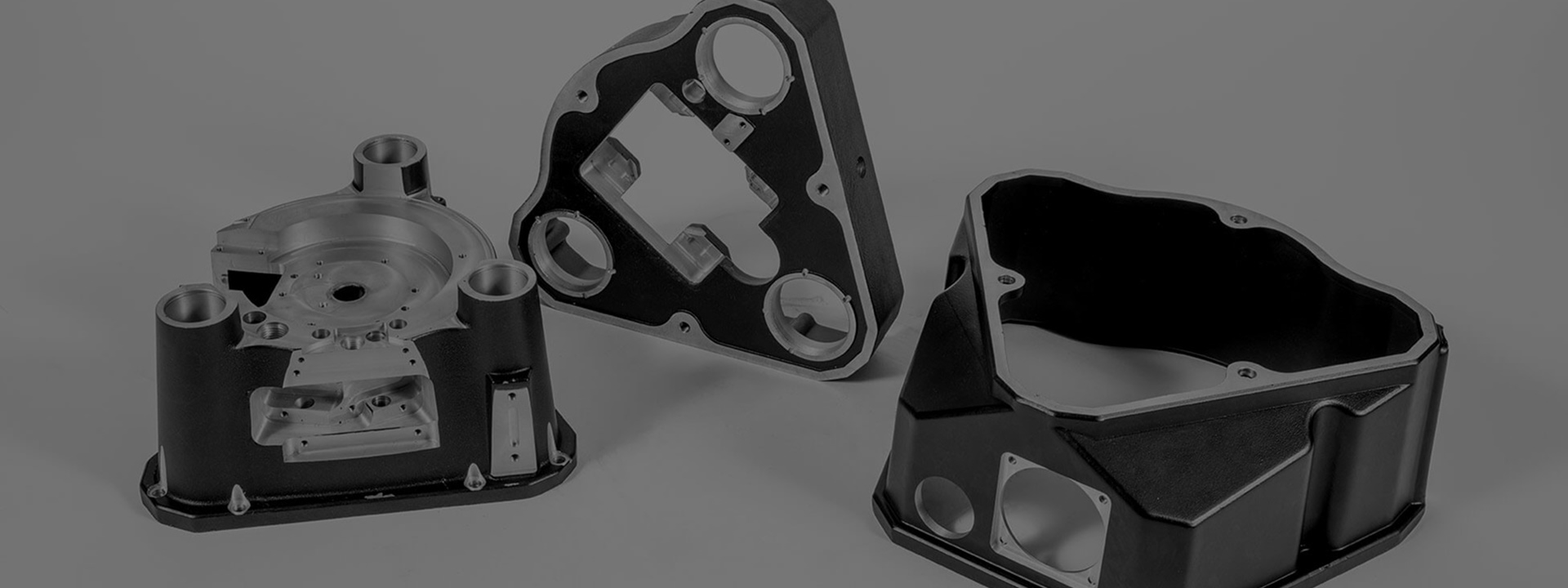

Custom Aluminum and Zinc Die Casting Capabilities

Our die casting workshop operates with 20 sets of machines ranging from 160T to 1650T, supporting small to large part production. We manage every step internally, from tooling design and mold simulation to casting, trimming, and finishing. With over 25 years of production experience, Meituo ensures dimensional stability, excellent density, and fine appearance for all die cast components.

Every die casting project at Meituo follows a strict process control system from raw material inspection to final dimensional verification. Our ISO9001 and IATF16949-certified procedures include real-time temperature monitoring, pressure regulation, and X-ray inspection for internal defects. By integrating QMS and MES systems, we ensure full traceability, consistent mechanical strength, and stable product performance for every order.

Quality and Process Control in Die Casting

Die Cast Metal Parts

Precision-Engineered Die Cast Components

We supply custom die cast housings, brackets, pump bodies, and heat sink parts used in vehicles, appliances, and industrial systems. Each part is processed under strict dimensional control and quality inspection to guarantee durability and consistency in mass production.

What Is Die Casting

Die casting is a manufacturing process that injects molten metal into a steel mold under high pressure. It enables the mass production of complex metal parts with high dimensional accuracy, smooth surfaces, and consistent mechanical performance. Meituo's die casting covers both aluminum and zinc alloys, offering excellent strength-to-weight ratios and superior corrosion resistance.

Types of Metal Die Casting

We mainly produce aluminum and zinc die castings. Aluminum die casting is ideal for lightweight, high-strength parts used in automotive and industrial applications. Zinc die casting provides excellent detail accuracy and a superior surface finish, perfect for smaller and decorative components. Both processes are supported by automated temperature control and real-time monitoring for consistent quality.

Advantages of Meituo's Die Casting

Meituo combines technical expertise with efficient production. Our in-house tooling team shortens development cycles, and advanced casting machines guarantee stable injection pressure and rapid solidification. Each batch is inspected for porosity, surface quality, and dimensional precision. With integrated machining and finishing, we deliver ready-to-assemble die cast components.

Applications of Die Cast Products

Our die cast components are widely used in automotive powertrain housings, appliance enclosures, communication device frames, and renewable energy systems. By adjusting alloy composition and mold design, we meet different mechanical and thermal requirements across diverse industries.

Die Casting Process

The die casting process includes mold design, alloy melting, injection, trimming, machining, and finishing. Each step is recorded digitally through our MES system to ensure full traceability. We focus on process stability—controlling mold temperature, injection speed, and cooling time—to maintain consistent metal structure and precision across all batches.

Sustainable and Automated Die Casting

With continuous investment in automation and process optimization, Meituo enhances efficiency and minimizes material waste. Our die casting lines feature energy-saving furnaces, automatic ladling systems, and digital temperature control, supporting sustainable manufacturing while maintaining consistent product quality.

FAQs